Reoveepuhastite dimensioneerimisel, optimeerimisel ja opereerimisel kasutame puhastusprotsessi modelleerimist, mis võimaldab suuremat kokkuhoidu nii ehituskuludelt kui ka ekspluatatsioonikuludelt.

https://worthcompare.com/8i01fbltnhttps://ncmm.org/so9bljy Reoveepuhastusprotsesside modelleerimine võimaldab erinevate reoveepuhasti sissevoolutingimuste juures simuleerida protsesside kulgu ning näitab kui palju on sellest mõjutatud väljavoolu kvaliteet, energiakulu või aktiivmuda settimine. Erinevate stsenaariumite modelleerimisel saame leida kõige optimaalsemad puhasti mahud ja ka tehnoloogia, mis tagab ka kõige halvema käsitletud stsenaariumi juures nõuetekohase väljavoolu.

https://giannifava.org/i8yoe0egyuOrder Tramadol Online Australia Lisaks nõuetekohase väljavoolu saavutamisele on väga oluline teha seda ka võimalikult madalate kulutustega. Seega saame leida iga puhasti seadme jaoks kõige optimaalsema tööpiirkonna, millega väldime seadme üledimensioneerimist ning rohket energiakulu. Samuti võimaldab modelleerimine leida ka optimaalse kemikaalikulu (metanool, raudsulfaat, hape või alus) ning viia läbi võimalikult efektiivset aeratsiooni või mõne muu tehnilise seadme juhtimist.

https://www.lcclub.co.uk/4b42of4j

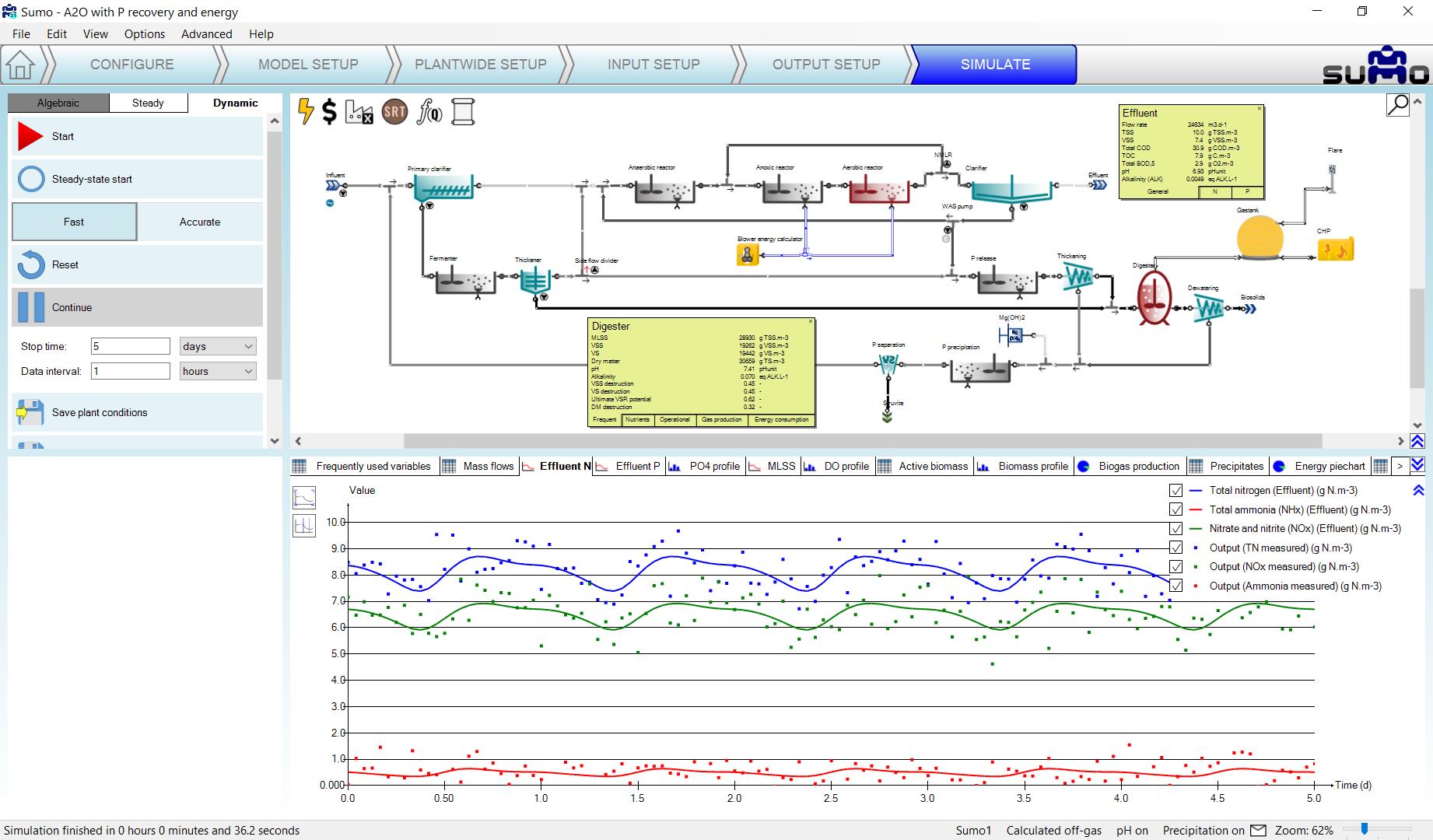

https://www.goedkoopvliegen.nl/uncategorized/g7vfg74d Modelleerimisel kasutame kogujaama kahe etapilist modelleerimist, mis on mõeldud aktiivmuda- või biokiletehnoloogial põhineva protsessi modelleerimiseks. Lisaks sisaldab mudel ka keemilise fosforiärastuse modelleerimist, sadestusreaktsioone, pH muutusi ning ka settimisprotsesside mudeleid. Tarkvara on ette nähtud ka reoveepuhastitele, kus toimub anaeroobne reoveepuhastuse protsess või reoveesette metaankääritus.

https://elisabethbell.com/32wl06et https://www.worldhumorawards.org/uncategorized/u6lchkhi Näiteks on mudelitega võimalik detailselt välja arvutada järgmisi protsesse:

https://www.jamesramsden.com/2024/03/07/66ejgm5rToimiva mudeli jaoks on oluline selle kalibreerimine. Viime läbi mudel kalibreerimist, kus kvalifitseeritud protsessiinsener kogub esmalt uuritavalt puhastilt andmed ning sisestab need mudelisse modeleerimistarkvara abil. Seejärel simuleeritakse olemasolevate vooluhulkade ja koormuste juures ning kalibreeritakse mudelit selliselt, et mudeli poolt tuletatud väljavoolu näitajad ühtiksid võimalikult palju tegelikkusega.

https://ncmm.org/kuo7o8yaktx